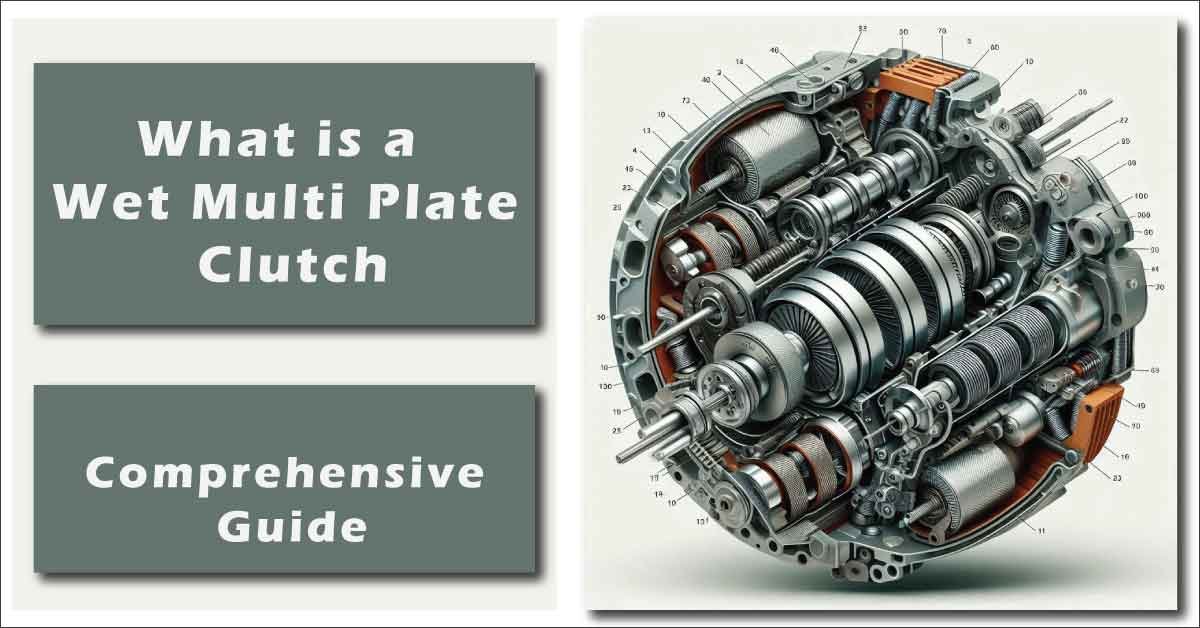

A wet multi plate clutch consists of an intricate arrangement of steel driven plates and advanced organic resin friction plates, all encased within a drum that spins around a central shaft. The term “wet” refers to the system being lubricated and cooled by oil, which enhances performance and longevity. This design allows for smooth engagement and disengagement, making it ideal for high-torque applications.

What is a Wet Multi Plate Clutch?

A wet multi plate clutch is a specialized type of clutch commonly used in automotive applications, particularly in motorcycles, high-performance cars, and certain industrial machinery. This clutch design features multiple friction plates that operate in a lubricating fluid, usually oil, allowing for smoother engagement and disengagement compared to dry clutches. Wet multi-plate clutches are particularly valued for their ability to handle high torque loads, dissipate heat effectively, and provide a more comfortable driving experience.

1. Structure and Functionality Of Wet Multi Plate Clutch

Design Features of wet multi plate clutch

The wet multi plate clutch consists of several key components that work together to enable its functionality:

| Component | Description |

|---|---|

| Friction Plates | Multiple plates made from friction material, providing the surface for engagement. |

| Pressure Plates | Plates that apply pressure to the friction plates to engage and disengage the clutch. |

| Oil Bath | A reservoir of oil that lubricates the clutch plates, reducing friction and wear. |

| Springs | Springs provide the necessary pressure for engaging the plates when needed. |

| Housing | Encloses the clutch assembly and contains the oil bath. |

Operating Principle

In a wet multi plate clutch, when the clutch lever is pulled (in manual applications) or when hydraulic pressure is applied (in automatic applications), the pressure plates compress the friction plates against each other. The oil bath reduces friction and facilitates smoother engagement and disengagement. The primary advantages of this setup are:

Heat Dissipation: The oil not only lubricates but also helps in dissipating heat generated during engagement, reducing the risk of clutch fade.

Smoother Operation: The presence of oil minimizes jerking movements, leading to a more seamless driving experience.

Also Read: Industrial Design: A Very Easy Guide for Beginners

Applications Wet Multi Plate Clutch

Wet multi-plate clutches are utilized in various applications due to their robust performance characteristics:

Automotive Applications

Motorcycles: Many high-performance motorcycles use wet multi-plate clutches to handle the high torque generated by powerful engines. The ability to dissipate heat effectively makes them suitable for racing and spirited riding.

Sports Cars: In high-performance sports cars, these clutches provide rapid engagement and disengagement, enhancing acceleration and shifting performance.

Industrial Applications

Heavy Machinery: In construction and industrial machinery, wet multi-plate clutches are used in hydraulic systems where high torque and heat dissipation are critical for efficient operation.

Marine Applications: Wet multi-plate clutches are often used in marine engines to provide reliable torque transfer under varying load conditions.

Advantages of Wet Multi Plate Clutches

The wet multi plate clutch offers several key advantages that make it a preferred choice in various applications:

| Advantage | Description |

|---|---|

| High Torque Capacity | The design allows for greater torque transfer due to multiple plates, making it ideal for performance applications. |

| Effective Heat Dissipation | The oil bath helps to manage heat, reducing the risk of thermal damage and clutch fade. |

| Smoother Engagement | Oil lubrication reduces friction, allowing for seamless operation during engagement and disengagement. |

| Longer Lifespan | Reduced wear and tear on components due to lubrication extends the overall lifespan of the clutch. |

| Reduced Noise and Vibration | The lubricated environment minimizes noise and vibrations during operation, leading to a more pleasant driving experience. |

Disadvantages of Wet Multi Plate Clutches

While there are many advantages to wet multi-plate clutches, there are also some potential downsides:

| Disadvantage | Description |

|---|---|

| Complexity | The design can be more complex compared to dry clutches, potentially leading to higher manufacturing and maintenance costs. |

| Weight | Wet clutches may add extra weight due to the oil reservoir and additional components. |

| Potential for Contamination | Oil can become contaminated over time, affecting performance and requiring regular maintenance and oil changes. |

Maintenance Considerations Wet Multi Plate Clutch

Maintaining a wet multi-plate clutch involves several critical steps to ensure optimal performance:

Regular Oil Changes: The oil in the clutch should be changed regularly to prevent contamination and maintain lubrication.

Inspection of Components: Periodic checks of the friction plates and springs are necessary to identify wear and replace them as needed.

Monitoring Performance: Any signs of slipping or difficulty in engagement should be addressed immediately to avoid further damage to the clutch system.

Also Read: Precision Machining Explained: Everything You Should Know

Conclusion

In conclusion, the wet multi plate clutch is a vital component in many high performance vehicles and industrial applications. Its unique design, featuring multiple friction plates operating in an oil bath, provides significant advantages in terms of torque capacity, heat dissipation, and smooth operation.

While there are some disadvantages, such as increased complexity and maintenance requirements, the benefits often outweigh these concerns, particularly in environments where performance and reliability are paramount.

As technology continues to evolve, the wet multi plate clutch will likely remain a crucial element in automotive engineering and beyond, offering a balance of performance and durability that meets the demands of modern vehicles and machinery. Understanding the functionality, advantages, and maintenance needs of wet multi plate clutches is essential for anyone involved in automotive design, repair, or performance enhancement.