What Is CNC: In the vast landscape of modern manufacturing, few technologies stand as towering monuments to precision and efficiency like Computer Numerical Control (CNC). This marvel of engineering seamlessly marries the digital realm with the tactile world of machining, offering a gateway to unparalleled levels of accuracy and repeatability. But beyond its mechanical prowess lies a story of innovation, empowerment, and transformative impact. Join me as we embark on a journey through the intricate realms of CNC, exploring its essence, evolution, and endless possibilities.

The Essence of CNC: Precision Perfected

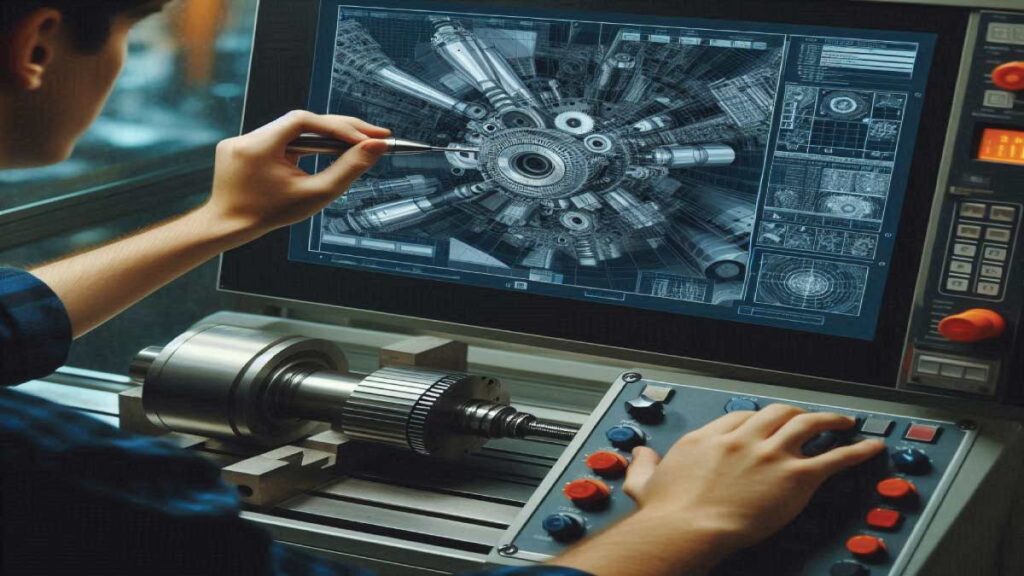

At its core, CNC is the embodiment of precision. Imagine a symphony where every note is meticulously crafted, every crescendo flawlessly executed. That’s the essence of CNC machining, a symphony of movements orchestrated by lines of code, translating digital blueprints into tangible realities with utmost accuracy.

What sets CNC apart is its ability to navigate the complexities of modern manufacturing with surgical precision. From intricate components in aerospace engineering to intricate designs in artistic creations, CNC machines offer a canvas where imagination knows no bounds. It’s not just about cutting metal or shaping wood; it’s about sculpting dreams into reality, one precise movement at a time.

The Evolution of CNC: From Humble Beginnings to Global Dominance

To understand the significance of CNC, we must rewind the tape of time and delve into its evolutionary origins. The roots of CNC can be traced back to the mid-20th century when pioneers like John T. Parsons and Frank L. Stulen envisioned a future where machines could be controlled by mathematical instructions. What began as a humble experiment soon blossomed into a revolution that would redefine the landscape of manufacturing forever.

Over the decades, CNC technology has undergone a metamorphosis, evolving from rudimentary punch card systems to sophisticated computerized controls. With each iteration, it has shattered barriers, pushing the boundaries of what was once thought possible. Today, CNC stands as a testament to human ingenuity, a beacon of innovation that illuminates the path towards a future limited only by our imagination.

The Endless Possibilities of CNC: Empowering Creativity

In the hands of skilled artisans and visionary engineers, CNC machines become instruments of creativity, transforming raw materials into works of art and engineering marvels. Whether it’s crafting intricate jewelry or fabricating complex prototypes, CNC unlocks a world of possibilities, empowering individuals to bring their boldest ideas to life.

But perhaps its greatest gift lies in democratizing access to manufacturing. In the past, realizing a design often required substantial resources and expertise. With CNC, however, the barriers to entry have been lowered, allowing enthusiasts and entrepreneurs alike to embark on their manufacturing journey with confidence. This democratization of production has spawned a renaissance of creativity, giving rise to a new generation of makers who dare to dream without constraints.

Challenges and Opportunities: Navigating the Terrain Ahead

While CNC has undoubtedly revolutionized manufacturing, it is not without its challenges. As technology advances at a breakneck pace, staying ahead of the curve requires continuous adaptation and learning. Moreover, concerns about job displacement and the ethical implications of automation loom large, casting a shadow over the promise of progress.

Yet, amidst these challenges lie opportunities for growth and innovation. By embracing emerging technologies like Artificial Intelligence and Internet of Things, CNC stands poised to usher in a new era of smart manufacturing where efficiency and sustainability go hand in hand. Moreover, initiatives aimed at upskilling the workforce and fostering collaboration between academia and industry hold the key to unlocking the full potential of CNC technology.

How Does CNC Technology Work?

In the intricate dance of modern manufacturing, Computer Numerical Control (CNC) technology emerges as a silent maestro, orchestrating movements with pinpoint accuracy and finesse. But beneath its sleek exterior lies a world of complexity and innovation waiting to be unraveled. So, how does CNC technology work? Join me as we embark on a journey through the inner workings of CNC, exploring its mechanics, algorithms, and transformative power.

The Heart of CNC: Understanding the Basics

At its core, CNC technology operates on a simple yet profound principle, translating digital instructions into physical movements. Picture a sculptor shaping clay according to a blueprint, except in this case, the sculptor is a machine, and the blueprint is a set of mathematical coordinates encoded in a language understood by computers.

The journey begins with a digital design, typically created using Computer-Aided Design (CAD) software. This design serves as the blueprint for the final product, detailing every contour, curve, and dimension with meticulous precision. Once the design is complete, it is translated into a set of instructions known as G-code – the language of CNC machines.

The Brain Behind the Brawn: G-code and CNC Controllers

G-code serves as the lingua franca of CNC machining, guiding the machine through a series of sequential commands that dictate its movements. These commands encompass a wide range of functions, from basic movements such as cutting and drilling to more complex operations like tool changes and spindle speed adjustments.

But who interprets these commands and ensures their execution with unwavering accuracy? Enter the CNC controller – the brain behind the brawn of CNC technology. This sophisticated device serves as the intermediary between the digital realm of G-code and the physical world of machining, translating instructions into precise movements with nanometer-level precision.

From Code to Action: The Mechanics of CNC Machining

With the G-code in hand and the CNC controller primed for action, it’s time to bring the design to life. The heart of every CNC machine lies in its mechanical components, the motors, actuators, and cutting tools that work in harmony to transform raw materials into finished products.

Motors drive the movement of the machine along multiple axes, allowing for precise positioning and intricate maneuvers. Meanwhile, actuators control auxiliary functions such as tool changes and coolant flow, ensuring seamless operation from start to finish. And let’s not forget the cutting tools themselves, the unsung heroes of CNC machining, whose razor-sharp edges carve through metal, wood, and composite materials with unparalleled efficiency.

The Human Touch: Programming and Operation

While CNC technology may seem like a realm dominated by machines and algorithms, it is ultimately the human touch that brings it to life. Skilled programmers and operators play a vital role in harnessing the full potential of CNC machines, from writing complex G-code programs to fine-tuning machine parameters for optimal performance.

Programming CNC machines requires a blend of technical expertise and creative problem-solving, as programmers must anticipate potential challenges and devise solutions that maximize efficiency and quality. Similarly, machine operators must possess a keen eye for detail and a steady hand, ensuring that every operation proceeds smoothly and safely.

Related Posts:

Pipe Bender: A Comprehensive Guide

How to Read a Tape Measure? Easy Explanation

10 Benefits of CNC Technology

In the ever-evolving landscape of modern manufacturing, Computer Numerical Control (CNC) technology stands as a beacon of innovation and efficiency. From precision engineering to creative craftsmanship, CNC offers a myriad of benefits that revolutionize the way we design, create, and produce. Join me as we explore 10 compelling reasons why CNC technology is a game-changer in today’s industrial landscape.

1. Precision Redefined

At the heart of CNC technology lies an unwavering commitment to precision. Unlike traditional machining methods, which rely on manual labor and are prone to human error, CNC machines execute commands with microscopic accuracy, ensuring consistent quality and dimensional accuracy with every cut, drill, and carve.

2. Enhanced Efficiency

In the fast-paced world of manufacturing, time is of the essence. CNC machines operate with unmatched speed and efficiency, minimizing downtime and maximizing productivity. With rapid tool changes, automated processes, and continuous operation, CNC technology streamlines production workflows and drives down costs.

3. Versatility Unlimited

Whether you’re working with metal, wood, plastics, or composites, CNC machines offer unparalleled versatility. With the ability to handle a wide range of materials and geometries, CNC technology empowers manufacturers to tackle diverse projects with ease, from intricate prototypes to large-scale production runs.

4. Consistent Quality

Quality is non-negotiable in today’s competitive marketplace, and CNC technology delivers consistency in spades. By eliminating variations caused by human error and ensuring repeatability across batches, CNC machines uphold the highest standards of quality control, earning the trust and loyalty of customers worldwide.

5. Complex Geometry Made Simple

Gone are the days of manual machining limitations. With CNC technology, even the most complex geometries are within reach. Whether it’s intricate contours, sharp angles, or smooth curves, CNC machines execute precise movements with ease, turning even the most ambitious designs into tangible realities.

6. Cost-Effective Production

In the quest for profitability, cost efficiency is paramount. CNC technology offers a cost-effective alternative to traditional machining methods, reducing labor costs, material wastage, and rework. By optimizing production processes and minimizing overheads, CNC machines deliver maximum value without compromising on quality.

7. Streamlined Prototyping

Innovation thrives on experimentation, and CNC technology facilitates rapid prototyping like never before. With quick setup times and on-the-fly adjustments, CNC machines empower designers and engineers to iterate rapidly, turning concepts into prototypes in record time. This agility accelerates the product development cycle, allowing companies to stay ahead of the curve in an ever-changing market.

8. Safety First

Safety is paramount in any manufacturing environment, and CNC technology prioritizes the well-being of operators and workers. By automating hazardous tasks and minimizing manual intervention, CNC machines reduce the risk of workplace accidents and injuries, creating a safer and more conducive working environment for all.

9. Environmental Sustainability

In an age of increasing environmental awareness, sustainability is no longer an option – it’s a necessity. CNC technology aligns with this ethos by minimizing material wastage, optimizing energy consumption, and reducing harmful emissions. By adopting CNC machines, manufacturers can tread lightly on the planet without compromising on performance or profitability.

10. Empowering Innovation

Above all, CNC technology empowers innovation. By democratizing access to advanced manufacturing capabilities, CNC machines unleash the creative potential of designers, engineers, and entrepreneurs worldwide. From small-scale workshops to multinational corporations, CNC technology levels the playing field, allowing anyone with a vision to turn their ideas into reality.

In Conclusion: Embracing the Future with Open Arms

As we draw the curtains on our exploration of CNC, one thing becomes abundantly clear: the journey is far from over. With each passing day, new horizons beckon, inviting us to embark on a voyage of discovery fueled by curiosity and conviction. In the ever-changing landscape of manufacturing, CNC remains a steadfast companion, guiding us towards a future where precision meets passion, and innovation knows no bounds.

So let us embrace the future with open arms, for in the realm of CNC, the possibilities are as limitless as the human imagination itself. As we stand on the cusp of a new era, let us remember that the greatest adventures await those who dare to dream, those who dare to create, and those who dare to defy the limits of what is possible.

Frequently Asked Questions About CNC Technology:

What is CNC technology, and how does it work?

CNC stands for Computer Numerical Control, a technology that uses computerized systems to control machine tools. It works by translating digital instructions, typically in the form of G-code, into precise movements of the machine’s cutting tools along multiple axes.

What are the main advantages of using CNC machines?

CNC machines offer a multitude of advantages, including unparalleled precision, enhanced efficiency, versatility across various materials, consistent quality, and the ability to produce complex geometries with ease.

Are CNC machines difficult to operate and program?

While CNC machines require specialized training to operate and program effectively, modern advancements in user interfaces and software have made them more user-friendly than ever before. With proper training and practice, operators and programmers can quickly become proficient in harnessing the full potential of CNC technology.

Can CNC machines be used for prototyping as well as production?

Absolutely! One of the key benefits of CNC technology is its versatility, making it ideal for both prototyping and production runs. CNC machines excel at rapid prototyping due to their quick setup times, on-the-fly adjustments, and ability to iterate designs with ease.

How do CNC machines contribute to workplace safety and environmental sustainability?

CNC machines prioritize workplace safety by automating hazardous tasks and minimizing manual intervention, thus reducing the risk of workplace accidents and injuries. Additionally, CNC technology promotes environmental sustainability by minimizing material wastage, optimizing energy consumption, and reducing harmful emissions compared to traditional machining methods.

ZAK Engineer is an experienced engineer with 15 years in the mechanical and industrial sectors. Holding advanced degrees and multiple certifications in engineering, he combines technical expertise with a passion for writing to provide valuable insights into engineering innovations and business strategies. His content empowers professionals to excel in their fields and stay updated with the latest industry trends.

1 thought on “What Is CNC? A Comprehensive Guide”