In mechanical engineering, stress is a fundamental concept that helps engineers understand how materials behave under different loads. Whether it’s a bridge, a machine part, or a structural beam, every component experiences some form of stress when force is applied. Understanding stress is crucial for designing safe, durable, and efficient mechanical systems.

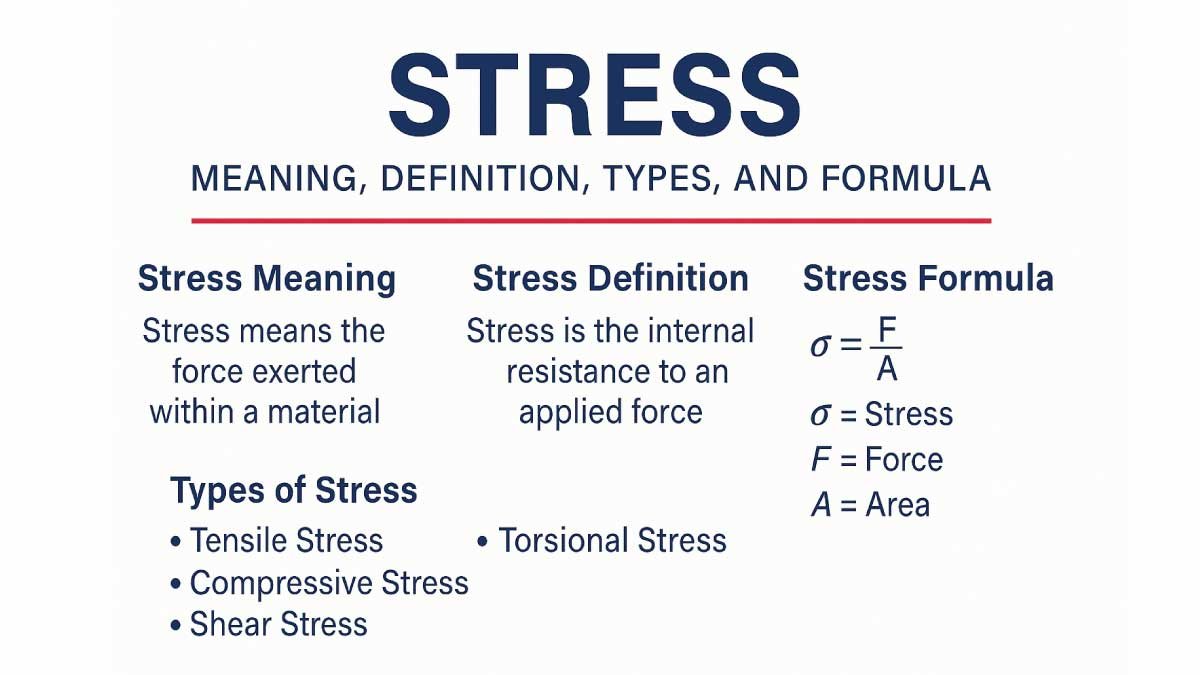

Stress meaning in simple terms is the internal resistance developed within a material when an external force acts upon it. It tells us how much pressure a material can handle before it deforms or breaks. The official stress definition in engineering is the force applied per unit area within materials. This concept is essential for analyzing the strength and performance of mechanical components.

To calculate stress accurately, engineers use the stress formula, which is:

Stress = Force / Area

This formula helps determine whether a material is suitable for specific applications or not.

There are various types of stress, including tensile stress, compressive stress, shear stress, torsional stress, and bending stress. Each type affects materials differently based on the direction and nature of the applied force. In this blog post, we will explore the meaning, definition, formula, and major types of stress in mechanical engineering.

✅ What is Stress?

In mechanical engineering, stress means the internal force or pressure experienced by a material when an external force is applied to it. When we pull, push, bend, or twist a material, it develops internal resistance. This internal resistance per unit area is called stress.

Stress is an important concept in designing machines, buildings, vehicles, and many other structures. If a material cannot handle the stress, it may bend, crack, or even break. That’s why engineers calculate stress to make sure the material or component is safe and strong enough.

There are different types of stress:

Tensile Stress – when a material is pulled.

Compressive Stress – when a material is pressed or squeezed.

Shear Stress – when forces act in opposite directions across the surface.

Torsional Stress – when a material is twisted.

The formula to calculate stress is:

Stress = Force / Area

It is measured in units like Pascal (Pa) or N/m².

Understanding stress helps engineers select the right materials for different applications. For example, bridges, airplanes, and car engines must be designed to handle various stresses to avoid failure.

Also Read:

✅ Stress Meaning:

In mechanical terms, stress means the internal force developed in a material when an external force is applied. It shows how much load a material can handle before it deforms or breaks. Stress tells engineers how strong and safe a material or part is under tension, compression, or twisting forces. It is calculated as force divided by area and is measured in Pascal (Pa).

✅ Stress Definition:

In mechanical engineering, stress is defined as the internal resistance offered by a material per unit area when subjected to an external force. It is a key factor in analyzing how materials behave under load. The mathematical formula for stress is:

Stress = Force / Area.

Stress helps determine whether a material can safely carry the applied load without failure. It plays a vital role in designing mechanical components like beams, shafts, gears, and machine parts. Stress is measured in units of Pascal (Pa), Newton per square meter (N/m²), or Megapascal (MPa).

Also Read:

✅ Stress Formula:

In mechanical engineering, stress is calculated using the basic formula:

Stress (σ) = Force (F) / Area (A)

This formula means that stress is the amount of force applied to a material divided by the area over which the force is applied. The force is measured in Newtons (N), and the area is measured in square meters (m²). The resulting unit of stress is Pascal (Pa) or N/m².

This formula helps engineers determine how much pressure a material can handle without breaking or deforming. It applies to tensile stress, compressive stress, and shear stress (with the proper force and area).

Example:

If 1000 N force is applied on an area of 0.01 m², then stress = 1000 / 0.01 = 100,000 Pa.

Also Read:

Stress Symbols:

✅ σ (Greek letter sigma)

Symbol: σ

Pronounced as: “Sigma”

Used for: General stress (including tensile and compressive stress)

Unit: Pascal (Pa) or N/m²

🔹 Example:

The formula for normal stress is:

σ = F / A

Where:

σ = Stress

F = Applied force (in Newtons)

A = Cross-sectional area (in m²)

🛠️ Other Stress Symbols:

τ (tau): Used for shear stress

σₜ: Tensile stress

σ𝚌: Compressive stress

Let me know if you’d like a chart or image showing these symbols!

Also Read:

A Complete Guide to Torque: Definition, Formula, Units, and More

✅ Types of Stress in Mechanical Engineering:

In mechanical engineering, stress is defined as the internal force experienced by a material when an external force is applied to it. It tells us how much force is acting on a specific area of the material. Stress is usually measured in Pascal (Pa) or N/m².

Understanding the types of stress is very important in designing safe and strong machines, buildings, bridges, and mechanical components. Different forces produce different types of stress. If the type and amount of stress are not calculated correctly, the part may bend, crack, or even break.

Let’s explore the main types of stress that occur in mechanical components:

1. Tensile Stress

Tensile stress occurs when a material is subjected to a pulling force. This type of stress tries to stretch the material. It is commonly found in cables, rods, and any part that is being pulled.

Example:

If you pull both ends of a steel rod, it gets longer. The internal resistance inside the rod is tensile stress.

Formula:

Tensile Stress = Force / Cross-sectional Area

Unit: Pascal (Pa) or N/m²

Tensile stress is important in bridges, ropes, and structural supports where parts are under tension.

2. Compressive Stress

Compressive stress is the opposite of tensile stress. It occurs when a material is compressed or pushed together. It tries to shorten the material.

Example:

A concrete column under a building experiences compressive stress from the load above.

Formula:

Compressive Stress = Force / Cross-sectional Area

Compressive stress is important in structural elements like walls, columns, and foundations.

3. Shear Stress

Shear stress develops when forces act in opposite directions across the same plane, trying to slide one part of the material over the other.

Example:

When you use scissors to cut paper, the paper experiences shear stress. In bolts, pins, and rivets, shear stress occurs when parts move in opposite directions.

Formula:

Shear Stress = Shear Force / Area

Shear stress is common in joints, shafts, and fasteners.

4. Torsional Stress

Torsional stress happens when a material is subjected to a twisting force, also known as torque. It is a form of shear stress due to rotation.

Example:

The shaft of a motor or a car axle experiences torsional stress as it transfers rotational motion.

Formula:

Torsional Stress = Torque × Radius / Polar Moment of Inertia

Torsional stress is crucial in shafts, gears, axles, and rotating machinery.

5. Bending Stress (Flexural Stress)

Bending stress occurs when a force causes a material to bend. In this case, one side of the material is in tension, and the other side is in compression.

Example:

A beam supported at both ends and loaded in the center will bend. The top part of the beam compresses, and the bottom part stretches.

Formula:

Bending Stress = (Bending Moment × Distance from Neutral Axis) / Moment of Inertia

Bending stress is seen in beams, levers, and all structural members that carry bending loads.

6. Thermal Stress (Bonus Type)

Thermal stress is not caused by external force but by temperature changes. When a material expands or contracts due to heating or cooling, and it is restricted from moving freely, it develops stress inside.

Example:

Railway tracks expand in the summer and contract in the winter. If there’s no space for movement, thermal stress develops, which can cause the track to bend.

Formula:

Thermal Stress = Modulus of Elasticity × Coefficient of Expansion × Temperature Change

Thermal stress is important in machines and structures exposed to varying temperatures.

🔍 Why Understanding Stress Types Matters

Each type of stress affects materials differently. A material that performs well under tension might fail under compression or bending. Engineers need to:

Choose the right material for the type of stress

Design parts that are safe and efficient

Avoid failure, cracks, and accidents

Ensure long-lasting performance of machines and structures

Knowing the types of stress helps engineers create smart, safe, and cost-effective designs in the real world.

Also Read:

🔧 Conclusion

Stress is a key concept in mechanical engineering that describes how materials respond to forces. By understanding the meaning and definition of stress, engineers can design safer and stronger structures and machine parts. Using the basic stress formula — force divided by area — helps calculate the amount of stress a material experiences. Knowing the different types of stress, such as tensile, compressive, shear, torsional, and bending stress, is important because each affects materials in unique ways. Proper stress analysis ensures materials don’t fail under load, making engineering designs reliable and durable. Whether you are working on bridges, shafts, or beams, understanding stress is essential to create efficient and long-lasting mechanical systems.

Also Read:

FAQs:

What is stress in mechanical engineering?

Stress is the internal force per unit area that develops inside a material when external forces act on it. It shows how much load a material can withstand before deforming or breaking. Stress helps engineers understand material behavior under tension, compression, bending, or twisting, allowing them to design safe and efficient mechanical parts.

How do you calculate stress?

Stress is calculated using the formula: Stress = Force / Area. The force applied on a material is divided by the cross-sectional area where the force acts. The result is measured in Pascals (Pa). This calculation helps engineers determine if a material can safely handle the applied load without failure.

What are the types of stress?

The main types of stress in mechanical engineering include tensile (pulling), compressive (pushing), shear (sliding), torsional (twisting), and bending stress. Each type affects materials differently, so understanding them is crucial for proper design and safety of mechanical components and structures.

What is the unit of stress?

The unit of stress is the Pascal (Pa), which equals one Newton per square meter (N/m²). Sometimes, MegaPascal (MPa) is used for larger values. Stress units show the amount of force applied over an area and are standard in engineering measurements.

What is tensile stress?

Tensile stress occurs when a material is subjected to a force that tries to stretch or pull it. This stress tries to elongate the material. It is important in cables, rods, and structural components that experience tension during operation.

What causes shear stress?

Shear stress is caused by forces applied in opposite directions on parallel surfaces, causing the material layers to slide over each other. This type of stress occurs in cutting tools, bolts, and other mechanical parts where sliding or twisting forces are present.