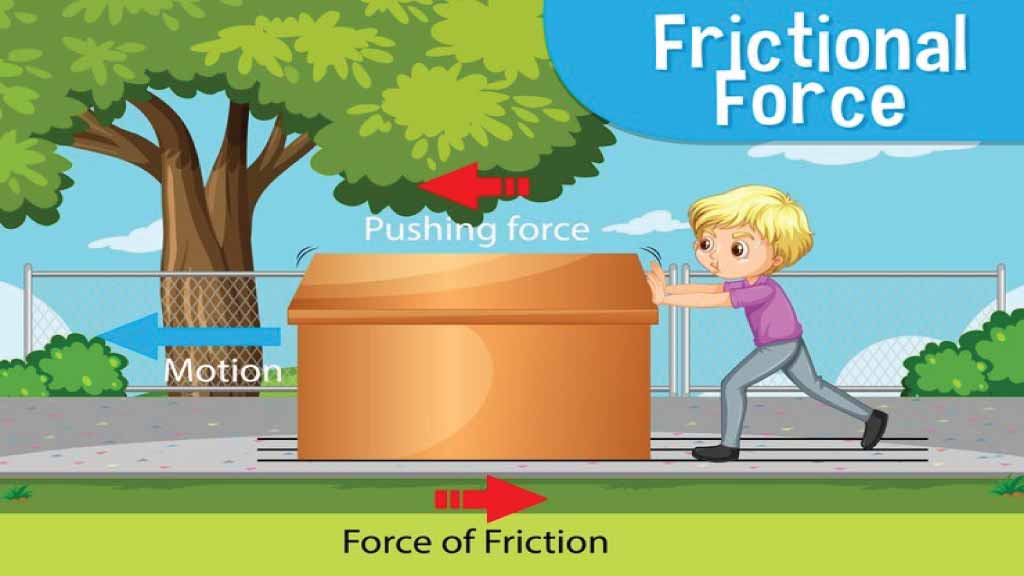

What is Friction? Friction is a force that acts in opposition to the movement or tendency of movement between two surfaces in contact. It arises from the interaction between surface irregularities when objects move against each other. Essentially, friction acts to slow down or prevent motion by converting kinetic energy into heat energy. This phenomenon is ubiquitous in our daily lives, present in activities as simple as walking or as complex as driving a car. Understanding what is friction is crucial in various fields, including engineering, physics, and mechanics. Engineers and designers carefully consider frictional effects when creating products, machinery, and infrastructure to ensure optimal performance and safety.

Moreover, what is friction plays a vital role in nature, influencing phenomena such as earthquakes and the motion of tectonic plates. By studying what is friction, scientists gain insights into fundamental principles governing motion and interaction at both macroscopic and microscopic scales, contributing to advancements in technology and scientific knowledge.

Types of Friction: Exploring the Forces That Slow Us Down

In the world of physics and engineering, friction is not a one size fits all concept. It comes in various forms, each with its own unique characteristics and effects. Understanding these different types of friction is crucial for designing efficient machinery, predicting natural phenomena, and even improving everyday tasks. In this article, we will delve into the intricacies of friction, exploring its three main types: static friction, kinetic friction, and rolling friction.

Static Friction:

This type of friction occurs between two surfaces that are stationary relative to each other. It’s what keeps a book from sliding off a table or prevents your car’s tires from skidding when parked on a steep incline. Static friction acts to oppose the initiation of motion, making it essential for maintaining stability and preventing objects from slipping or sliding unintentionally.

Kinetic Friction:

Once an object overcomes static friction and starts moving, it encounters kinetic friction. Unlike static friction, which acts to prevent motion, kinetic friction opposes the object’s ongoing motion. This is the force responsible for slowing down a sliding box or making it harder to push a heavy object across the floor. Kinetic friction is influenced by factors such as the roughness of the surfaces in contact and the force pressing them together.

Rolling Friction:

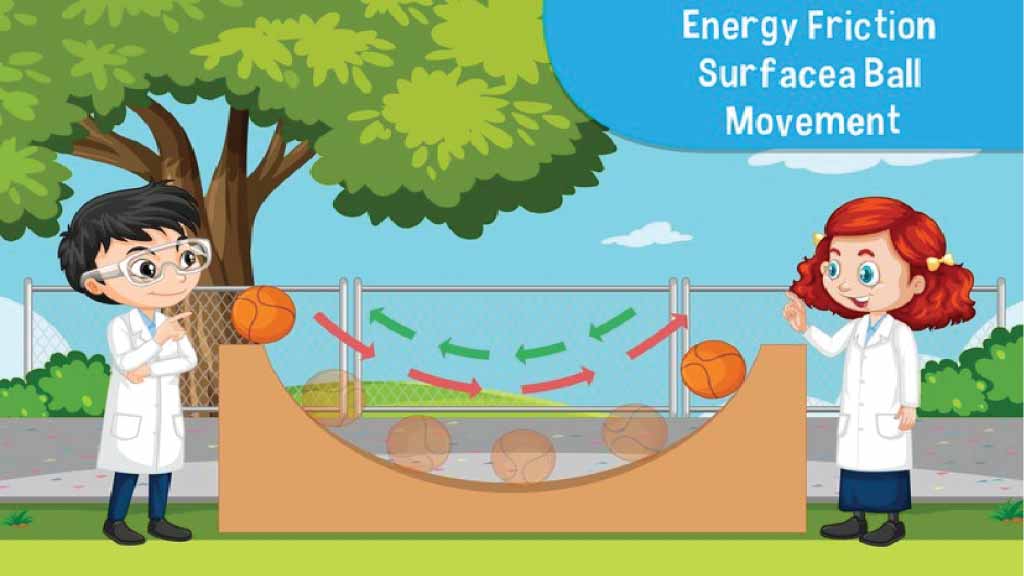

When an object rolls along a surface, it experiences rolling friction. This type of friction occurs between the rolling object and the surface it rolls on, such as the interaction between a car’s tires and the road. Rolling friction is generally lower than kinetic friction, making it more efficient for moving objects over extended distances. It plays a significant role in transportation, machinery, and various mechanical systems.

By understanding the nuances of static, kinetic, and rolling friction, engineers, scientists, and designers can optimize systems for efficiency, minimize wear and tear, and enhance performance across a wide range of applications. So, the next time you encounter resistance in your daily activities, remember that friction comes in different forms, each with its own story to tell.

What is Friction: How to Find Friction Force:

To find the friction force between two surfaces, you typically follow these steps:

Determine the coefficient of friction:

The coefficient of friction (often denoted as μ) represents the relationship between the force of friction and the normal force pressing the surfaces together. It depends on the materials and surface conditions involved. Look up or measure the coefficient of friction for the specific materials in your scenario.

Calculate the normal force:

The normal force (N) is the perpendicular force exerted by one surface on another when they are in contact. It’s equal to the weight of an object pressing against a surface. For example, if an object with a mass of m is placed on a flat surface, the normal force N equals mg, where g is the acceleration due to gravity (approximately 9.8 m/s² on Earth).

Apply the formula: Once you have the coefficient of friction and the normal force, you can use the formula for friction force:

The equation for frictional force is given by multiplying the coefficient of friction (μ) by the normal force (N). This results in the friction force (Ff).

Plug in the values you have determined for μ and N, and then calculate the friction force.

It’s important to note that the direction of the friction force opposes the direction of motion or impending motion between the surfaces. If the object is at rest, the friction force acts to prevent motion (static friction). If the object is already in motion, the friction force opposes the motion (kinetic friction).

What is Friction: Finding the Coefficient of Friction:

To find the coefficient of friction between two surfaces, you can conduct experiments or consult available data. Here’s how:

Conduct experiments:

You can directly measure the coefficient of friction by conducting experiments with the specific materials and surface conditions involved. For example, you might use a simple setup involving a block on a flat surface and gradually increase the angle of the surface until the block begins to slide. By measuring the angle at which sliding starts and knowing the applied force, you can calculate the coefficient of friction.

Use available data:

Many sources provide tables or databases containing known coefficients of friction for various materials and surface combinations. These resources may include textbooks, engineering handbooks, or online databases. Look for information that matches your specific materials and conditions as closely as possible.

Consult manufacturer specifications:

If the materials you are working with are commonly used in engineering or manufacturing, the manufacturer may provide specifications that include the coefficient of friction. Check product documentation or contact the manufacturer directly for this information.

Consider empirical formulas:

In some cases, empirical formulas or models may provide estimates of the coefficient of friction based on material properties or surface characteristics. While these estimates may not be as precise as direct measurements, they can serve as a starting point for analysis.

Remember that the coefficient of friction can vary depending on factors such as surface roughness, temperature, and the presence of lubricants or contaminants. Therefore, it’s essential to choose or measure the coefficient of friction that best reflects the specific conditions of your scenario.

What is Friction: How to Calculate Friction Accurately:

To calculate friction, you typically use the formula:

Friction = normal force × coefficient of friction

Here’s how you can calculate friction step by step:

Determine the coefficient of friction:

The coefficient of friction (μ) represents the relationship between the force of friction and the normal force pressing the surfaces together. This coefficient depends on the materials and surface conditions involved. Look up or measure the coefficient of friction for the specific materials in your scenario.

Calculate the normal force:

The normal force (N) is the perpendicular force exerted by one surface on another when they are in contact. It’s equal to the weight of an object pressing against a surface. For example, if an object with a mass (m) is placed on a flat surface, the normal force (N) equals mass times the acceleration due to gravity (g), i.e., N = m * g, where g is approximately 9.8 m/s² on Earth.

Plug in the values and calculate:

Once you have the coefficient of friction (μ) and the normal force (N), you can use the formula:

Friction = normal force × coefficient of friction

Simply multiply the coefficient of friction by the normal force to find the frictional force.

Remember, the direction of the friction force opposes the direction of motion or impending motion between the surfaces. If the object is at rest, the friction force acts to prevent motion (static friction). If the object is already in motion, the friction force opposes the motion (kinetic friction).

Finding the Coefficient of Friction:

To calculate the coefficient of friction between two surfaces, you typically follow these steps:

Measure the Normal Force (N):

The normal force is the force exerted by one surface on another when they are in contact. It’s perpendicular to the surfaces. You can calculate the normal force by multiplying the mass of the object pressing the surfaces together by the acceleration due to gravity (approximately 9.8 m/s² on Earth).

Normal Force (N) = acceleration due to gravity (g) × mass (m)

Apply a Known Force Parallel to the Surfaces:

Apply a force parallel to the surfaces in question, gradually increasing it until motion occurs or until you reach a specific condition, depending on the type of experiment you are conducting. Measure the applied force (F).

Calculate the Coefficient of Friction (μ):

Once motion occurs or your experiment condition is met, note the force required. The coefficient of the friction can be calculated using the formula:

Coefficient of Friction (μ) = Force of Friction / Normal Force (N)

Here, the force of friction (Ff) is the force required to overcome static friction (if motion hasn’t yet occurred) or the force opposing motion (kinetic friction).

Repeat for Accuracy:

It’s often beneficial to repeat the experiment multiple times to ensure accuracy and account for any variability in measurements.

By following these steps and conducting experiments with different surfaces and conditions, you can determine the coefficient of friction for your specific scenario. Remember that the coefficient of friction may vary based on factors such as surface roughness, temperature, and the presence of lubricants or contaminants.

Understanding What Are Mechanical Components is essential for anyone interested in the building blocks of machinery. Additionally, What is Precision Machining reveals how these components are crafted with extreme accuracy. Please read our detailed and easy, ultimate guide on these topics to explore their importance in engineering. Don’t miss the full post!

Conclusion About What Is Friction:

ZAK Engineer is an experienced engineer with 15 years in the mechanical and industrial sectors. Holding advanced degrees and multiple certifications in engineering, he combines technical expertise with a passion for writing to provide valuable insights into engineering innovations and business strategies. His content empowers professionals to excel in their fields and stay updated with the latest industry trends.