Types of Saws stand as indispensable instruments in a multitude of industries and DIY projects, meticulously designed to cut through various materials with unparalleled precision and efficiency. From woodworking to construction, each saw type is meticulously tailored to cater to specific tasks and materials, boasting unique features and capabilities that cater to diverse needs. In this comprehensive guide, we embark on an in-depth exploration of the top 10 types of saws, meticulously examining their materials, functionalities, and applications. By delving into the intricacies of each saw variant, we aim to equip readers with a comprehensive understanding of these essential tools.

Whether you are a seasoned professional or a DIY enthusiast, this guide serves as a valuable resource for selecting the right saw for your specific projects and achieving optimal results with precision and ease.

10 Different Types of Saws

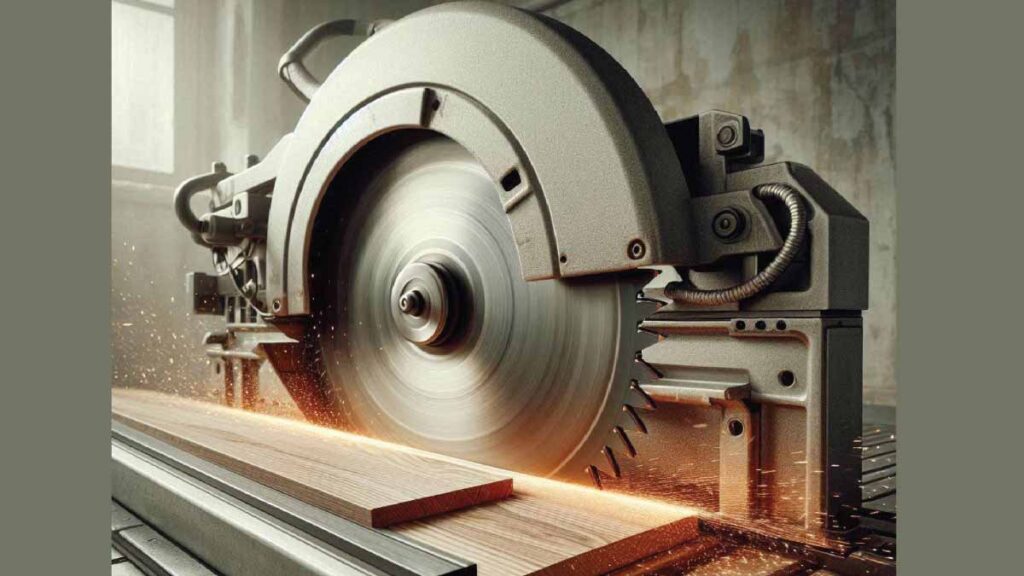

1. Circular Saw:

Circular saws, typically made of steel with carbide tipped blades, stand as versatile power tools capable of making straight cuts in wood, metal, plastic, and various other materials. Commonly found in woodworking, construction, and DIY projects, circular saws excel in tasks such as cutting lumber, plywood, and framing materials with precision and efficiency. The carbide tipped blades ensure durability and longevity, even when subjected to rigorous cutting tasks. Whether it’s framing a new structure, building furniture, or completing home renovation projects, circular saws offer the flexibility and power needed to tackle a wide range of cutting applications.

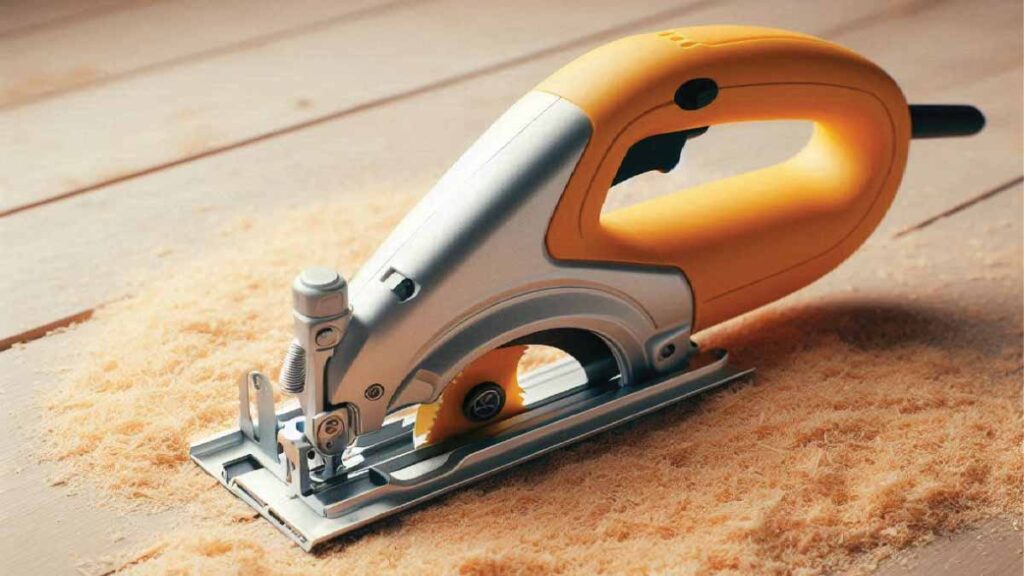

2. Jig saw:

Crafted from steel with toothed blades, jigsaws emerge as handheld power saws equipped with a reciprocating blade, ideal for crafting curved and intricate cuts in wood, metal, plastic, and other materials. Widely utilized in woodworking, metalworking, and crafts, jigsaws excel in cutting curves, circles, and irregular shapes with precision and ease. The toothed blades ensure efficient material removal while allowing for intricate detailing and creative expression. From crafting custom furniture pieces to shaping metal art, jigsaws empower artisans and DIY enthusiasts to bring their creative visions to life with finesse and accuracy.

3. Reciprocating Saw:

Manufactured from steel with toothed blades, reciprocating saws, also known as sabre saws or sawzalls, feature a push and pull motion of the blade, making them ideal for demolition, pruning, and cutting through various materials such as wood, metal, plastic, and even masonry. Widely employed in construction, remodeling, and landscaping projects, reciprocating saws offer unmatched versatility and power for tackling a myriad of cutting tasks. Whether it’s demolishing old structures, trimming tree branches, or cutting through stubborn materials, reciprocating saws deliver reliable performance and efficiency in challenging environments.

4. Miter Saw:

Constructed from steel with carbide-tipped blades, miter saws, also known as chop saws, emerge as specialized power saws designed for making accurate crosscuts and miter cuts in wood, metal, and plastic. Essential in woodworking, trim work, and framing projects, miter saws excel in cutting molding, trim, and framing components at precise angles, ensuring seamless joints and professional finishes. The carbide-tipped blades ensure clean and precise cuts, even in dense materials, allowing craftsmen and contractors to achieve impeccable results with every use.

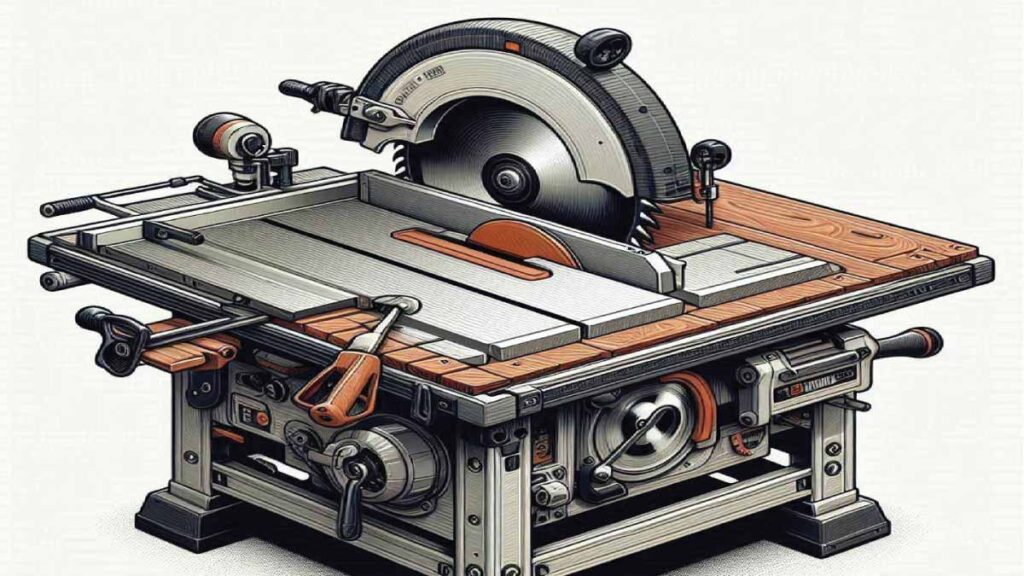

5. Table Saw:

Crafted from steel with carbide tipped blades, table saws emerge as stationary power saws equipped with a circular blade protruding through a flat surface, allowing for precise rip cuts and crosscuts in wood, plastic, and other materials. Indispensable in woodworking shops and construction sites, table saws serve as essential tools for cutting large panels, sheets, and boards with accuracy and efficiency. The carbide-tipped blades ensure smooth and clean cuts, even in thick and dense materials, enabling craftsmen and contractors to tackle large-scale projects with confidence and precision.

Related Posts:

Exploring 10 Types of File Tools (Pictures): Materials and Uses

25 Different Axe Types: 2024 Update Information

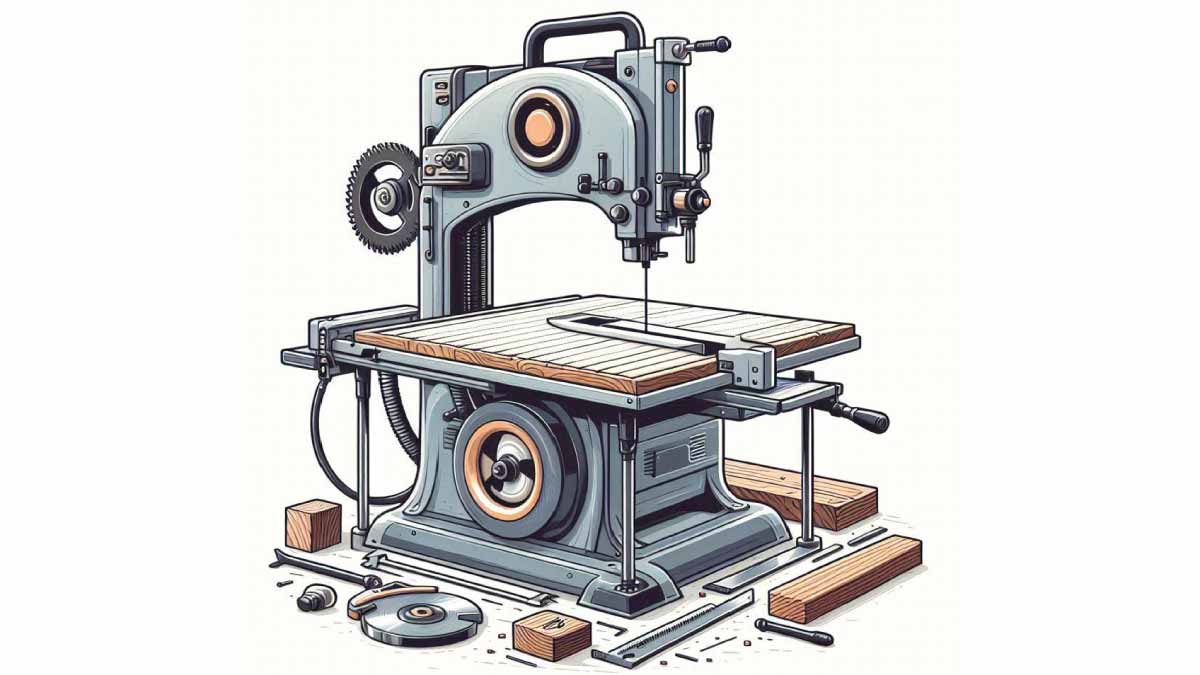

6. Band Saw:

Crafted primarily from steel with a continuous loop of toothed blades, band saws emerge as versatile tools ideal for cutting curves, irregular shapes, and straight lines in a variety of materials including wood, metal, plastic, and more. With their unique design featuring a continuous loop of toothed blades stretched between two wheels, band saws offer exceptional versatility and precision in cutting operations. Woodworkers, metalworkers, and even butchers rely on band saws for their ability to tackle a wide range of cutting tasks with ease and accuracy. Whether it’s shaping intricate designs in woodworking projects, cutting metal components for fabrication, or slicing meat and bone in butcher shops, band saws stand as indispensable tools in various industries and crafts.

7. Scroll Saw:

Typically constructed from steel with fine-toothed blades, scroll saws are specialized power saws meticulously designed for making intricate and detailed cuts in thin materials such as wood, plastic, and metal. Renowned for their precision and control, scroll saws excel in crafts, model making, and scrollwork, allowing artisans to create elaborate designs, fretwork, and decorative patterns with ease. The fine-toothed blades of scroll saws ensure clean and precise cuts, even in delicate materials, enabling craftsmen to achieve intricate detailing and flawless finishes in their projects. From crafting intricate wooden ornaments to designing intricate metalwork, scroll saws empower artisans to unleash their creativity and bring their artistic visions to life with precision and finesse.

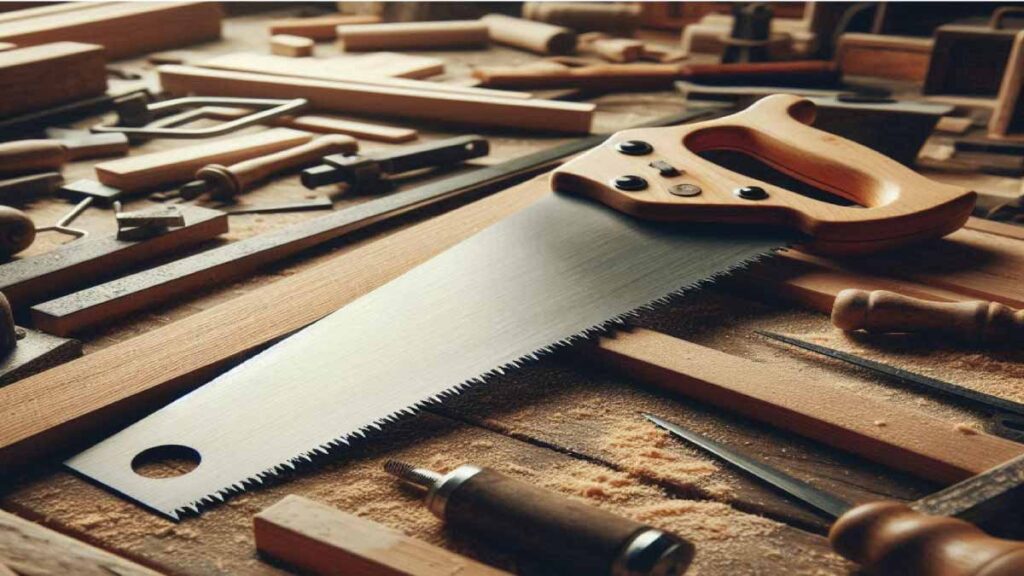

8. Hand Saw:

Traditionally crafted from steel with toothed blades, hand saws remain indispensable manual tools featuring a straight blade and a handle, used for making straight and precise cuts in wood, plastic, and other materials. While modern versions may incorporate high-carbon steel or other alloys for enhanced durability and performance, the basic design and functionality of hand saws remain unchanged. Versatile and reliable, hand saws find application in woodworking, carpentry, and DIY projects, serving as go to tools for tasks such as cutting lumber, trimming branches, and even cutting PVC pipes. With their simplicity and effectiveness, hand saws continue to be cherished tools in the toolboxes of craftsmen and DIY enthusiasts alike.

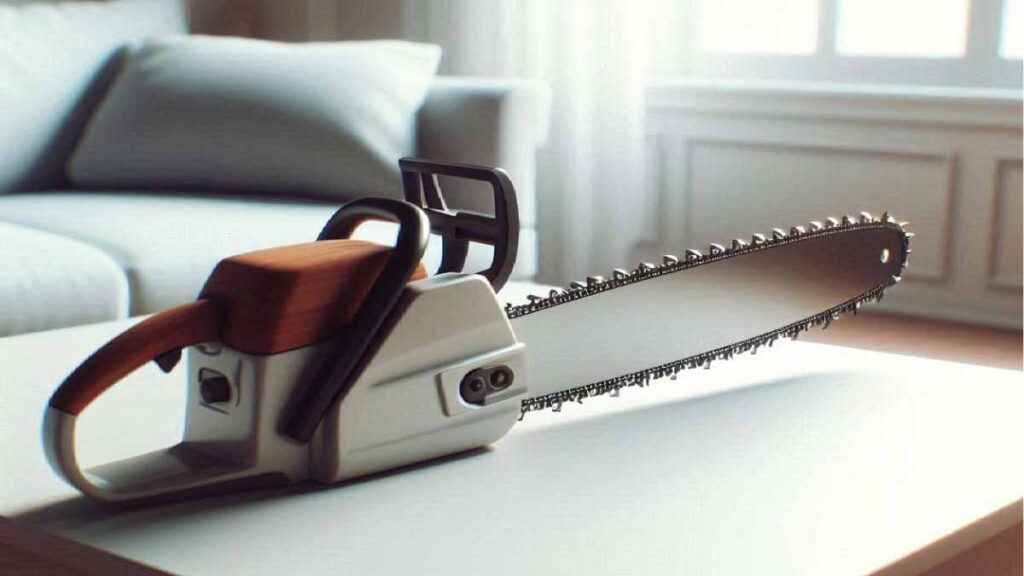

9. Chainsaw:

Typically constructed from steel with a chain fitted with toothed blades, chainsaws emerge as powerful and portable tools equipped with a rotating chain, used for cutting through large logs, trees, and branches in forestry, landscaping, and tree maintenance applications. Renowned for their formidable cutting capabilities, chainsaws excel in handling tough materials such as wood, making them indispensable tools in logging, storm cleanup, and construction projects. Whether it’s felling trees, pruning branches, or cutting firewood, chainsaws offer unmatched power and efficiency, enabling operators to tackle challenging cutting tasks with ease and precision.

10. Panel Saw:

Crafted primarily from steel with a vertical frame and horizontal cutting mechanism, panel saws stand as stationary tools meticulously designed for cutting large panels, sheets, and boards with precision and efficiency. Commonly found in woodworking shops, carpentry workshops, and manufacturing facilities, panel saws offer unmatched accuracy and productivity in cutting plywood, MDF, and other sheet materials into smaller pieces or precise dimensions. With their robust construction and advanced cutting mechanisms, panel saws streamline the process of panel cutting, allowing craftsmen and manufacturers to achieve precise cuts and maximize productivity in their operations.

Conclusion About Types Of Saws:

FAQs about Saws Types:

What are the main types of saws used in woodworking?

The main types of saws used in woodworking include circular saws, jigsaws, miter saws, band saws, and table saws. Each type is tailored to specific cutting tasks and offers unique features for woodworking projects.

Can I use the same saw for cutting different materials?

While some saws are versatile and can cut through various materials like wood, metal, and plastic, it’s essential to choose the right saw for the specific material and task at hand. Using the appropriate saw ensures clean cuts and prevents damage to the saw and the material being cut.

How do I choose the right saw for my project?

When choosing a saw for your project, consider factors such as the type of material you’re cutting, the desired cut type (straight, curved, angled), the size and complexity of the project, and your skill level. Researching different saw types and their capabilities can help you make an informed decision.

Are there safety precautions I should follow when using saws?

Yes, safety is paramount when using saws. Always wear appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, and gloves. Follow the manufacturer’s instructions and guidelines for operating the saw safely, and ensure the workpiece is securely clamped or supported to prevent accidents.

How do I maintain and care for my saws?

Proper maintenance is crucial for keeping your saws in optimal condition. Regularly clean saw blades and remove any debris or buildup to ensure smooth and efficient cutting. Keep saws lubricated according to the manufacturer’s recommendations, and store them in a clean, dry place to prevent rust and damage. Additionally, inspect saws for wear and damage regularly, and replace blades or parts as needed to maintain performance and safety.